We committed to the research and development and application innovation of intelligent robots, focusing on the research and development, production, sales and service of intelligent robotic arms and other intelligent hardware products.

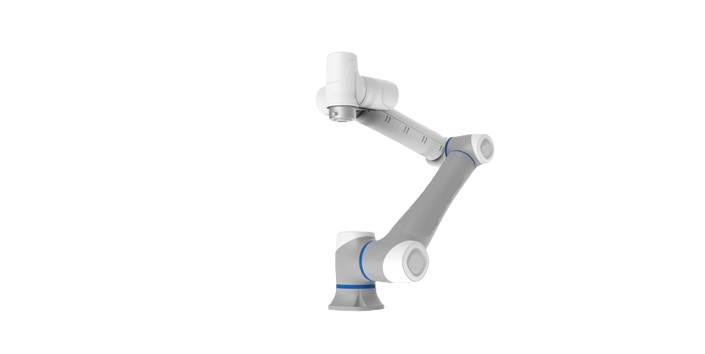

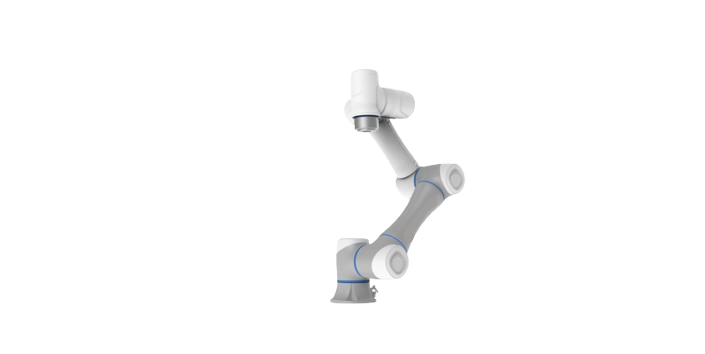

The new generation of collaborative robot CRA series adopts high-performance integrated joints and increases the cycle time by 25%.Efficiency reaches new heights, using new control cabinet and DobotStudio Pro system software, safety,Stability and scalability are comprehensively improved, taking human-machine collaboration to a new level.

Top speedBrand new integrated joint, the joint speed is increased to the industry’s fastest 223°/s.Meet more application scenarios, which can increase the production cycle time of typical applications such as material handling by 25%.Create higher economic benefits.

The joint servo uses the EtherCAT bus, which has hundreds of megabits of bandwidth and millisecond-level joint response.speed, significantly improving the robot's movement speed and trajectory smoothness,Enable robots to perform various tasks more efficiently.

Each robot is precisely calibrated using a laser tracker and has an absolute positioning accuracy of less than 0.4mm. It can easily handle more high-precision production tasks and bring better consistency and quality assurance to production.

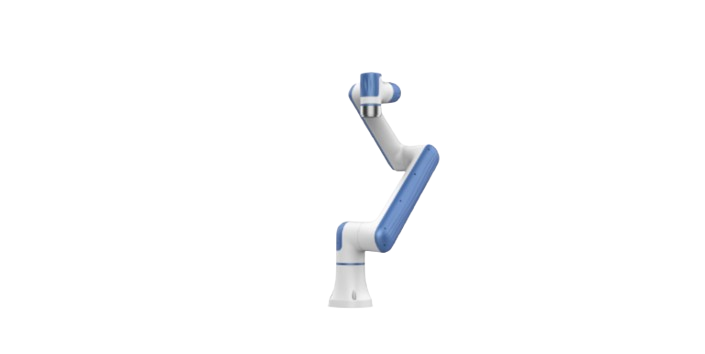

The Nova series of collaborative robots have two payloads of 2 kg and 5 kg. They have an extremely lightweight body design, are simple and easy to operate without thresholds, and are equipped with multiple safety protection technologies. They can easily control multiple intelligent new business scenarios and meet the needs of coffee, tea, ice cream, etc. It meets the needs of human-machine collaboration in commercial scenarios such as popcorn, restaurant food delivery, moxibustion therapy, health massage, and ultrasound examination; it also supports customized appearance colors to quickly match various brand styles.

The Nova series has an arm length of 625-850 mm, a slim and lightweight body that reduces weight by 33%-44% and volume by 20%. It is equipped with a palm-sized mini chassis and can be flexibly deployed in different commercial spaces without changing the store layout.

Trajectory reproduction technology and minimalist graphical programming standardize retail and catering operation processes. No programming experience is required, and working procedures can be quickly established with simple training. It supports cloud synchronization, real-time monitoring of robot status and other functions, and can quickly realize simultaneous intelligent upgrades in multiple stores.

High sensitivity, 5-level adjustable protection level, rapid response and timely stop within 0.01 s of touch detection, fully ensuring human safety. It supports intelligent sensing of human body movements and automatic locking posture when power is off. Multiple safety technologies protect human-machine collaboration in commercial scenarios.

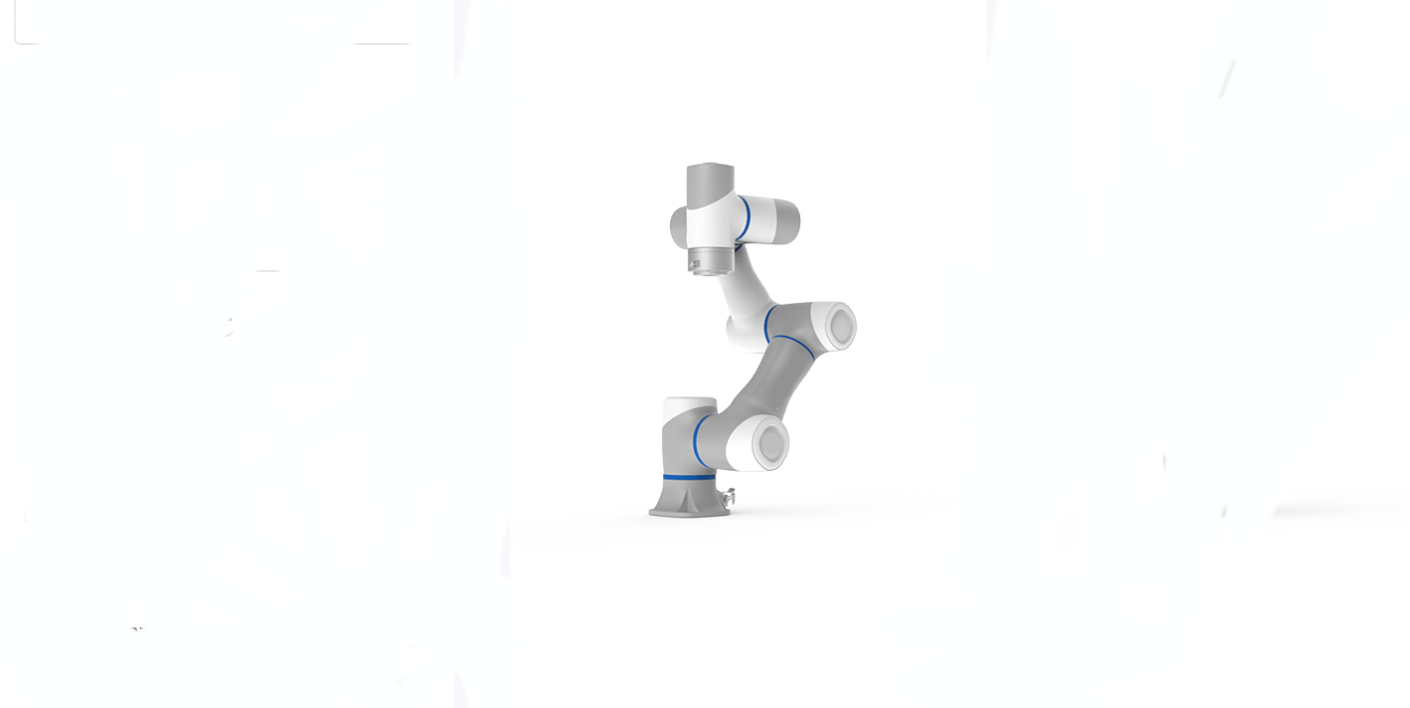

The CR series collaborative robot has six payloads of 3 kg, 5 kg, 7 kg, 10 kg, 12 kg, and 16 kg, with an accuracy of up to ±0.02 mm. It has the characteristics of safe collaboration, flexible deployment, easy to learn and use, and can quickly Matching various industry applications, it is very suitable for automobile, 3C, semiconductor, medical, chemical, new retail and other industries. It greatly meets customers' needs for flexible automation, can significantly reduce corporate costs and improve production efficiency.

The CRS series collaborative robot is an upgraded version of the CR series collaborative robot. It adds a cross-border safety skin non-contact collision detection solution and has unparalleled safety. At the same time, it continues the advantages of the previous generation product such as flexibility, easy deployment, and high precision. Currently, the CRS series is designed with three loads of 3 kg, 5 kg, and 10 kg. It is suitable for many industries such as automobiles, 3C, and home appliances. Especially in human-machine collaboration scenarios, it can better solve customers' needs for both safety and efficiency. .

The CRS series is equipped with self-developed technology - flexible safety skin, which realizes active safety protection through non-contact collision detection technology, maximizing the safety and operating efficiency of human-machine collaboration.

Unlike traditional collaborative robots that stop when they detect a collision, robots with safety skins can sense contact objects within 15 cm and achieve safe shutdown without contact between the robot and the human body, greatly improving the safety of human-machine collaboration. Sex, it can also ensure safety under high-speed movement.

Under the protection of the safety skin, the robot does not need to slow down in advance, and can increase the human-machine collaboration speed from 0.25 m/s to 1 m/s, increasing the human-machine collaboration efficiency by 4 times.

The CRS series provides three major programming methods: graphical programming, teaching reproduction, and script programming, which are suitable for use by personnel at different stages. Through rich plug-and-play ecological components and process package support, applications such as loading and unloading, assembly, gluing, and polishing can be quickly integrated, and even more intelligent flexible automation solutions such as disordered sorting and dynamic screwing can be easily created.

MG400 is an industrial-grade desktop four-axis collaborative robot with a body base that occupies an area smaller than A4 paper. It is flexible and easy to deploy, easy to use, and safe for collaboration. It is specially designed for diversified and small-batch automated production needs. The maximum load of 750 g and the arm length of 440 mm fully meet the needs of lightweight desktop applications. The human-machine collaboration features such as dragging and teaching, collision detection, etc. can make the MG400 truly meet the rapid deployment applications of production lines and is a high-end solution for automated and intelligent production. The best value for money.

In order to make full use of the production space and easily integrate into the existing production environment, the MG400 adopts a compact design integrating the controller and body. The base area is only 190 mm

MG400 uses a servo motor with a high-precision absolute encoder, and cooperates with a self-developed servo drive and controller to achieve a repeatable positioning accuracy of ±0.05 mm. Through the controller's vibration suppression algorithm, the repetitive positioning accuracy bandwidth stabilization time is accelerated by 60% and the residual vibration is reduced by 70% while ensuring the accuracy of the robot's multi-axis linkage spatial trajectory.

The product has the advantages of high precision, large range, complete functions, and support for secondary development. At the same time, it integrates the cutting-edge intelligent software and hardware platform of Yuejiang technology. It is very suitable for the intelligent manufacturing process in the light industry and is capable of handling more complex process sites.

It has built-in collision detection safety protection function and can cooperate with humans worry-free. The forearm is 40% narrower than traditional industrial robot arms, effectively reducing accidental collisions and damage to the machine.

The new incremental differential encoder interface expands dynamic grabbing and dynamic tracking applications. Supports parallel processing such as multi-threading and IO control during motion, effectively shortening the robot's movement rhythm.

Magician E6 is a desktop six-axis collaborative robot specially developed for education and research. It has the performance of an industrial robot and supports a variety of industrial expansion accessories. It can truly restore automation application scenarios and create an immersive teaching and research experience. Magician E6 provides a wealth of secondary development interfaces, tailors a course system covering robot structure and control principles, opens the door to innovation for teaching and scientific research, and provides the best practice platform for science and education in artificial intelligence, intelligent manufacturing and other fields. .

The streamlined body design combined with the collision detection function makes the operation safer. With the ring indicator light, the operating status of the robot can be grasped in real time, effectively reducing the user's collision risk.

The body is compact and light in weight. It can be installed on the desktop to start the installation. It is simple and flexible. The integrated design of the robot and controller eliminates the need for complicated wiring and can be plugged in and used.

Based on the self-developed trajectory reproduction technology, trajectory recording can be easily completed by dragging and teaching. It supports graphical programming and can be quickly started with zero basic knowledge. It is simple and easy to use and can be operated by everyone.